"According to news reports, the explosions in China took place at a warehouse, which contained hazardous and flammable chemicals, including calcium carbide, sodium cyanide, potassium nitrate, ammonium nitrate and sodium nitrate. Calcium carbide reacts with water to create highly explosive acetylene, which may have triggered off the blasts," she explains. "Indications are that the firefighters were on site before the explosions. The volatility of the chemicals means the fire was especially unpredictable and dangerous to approach.

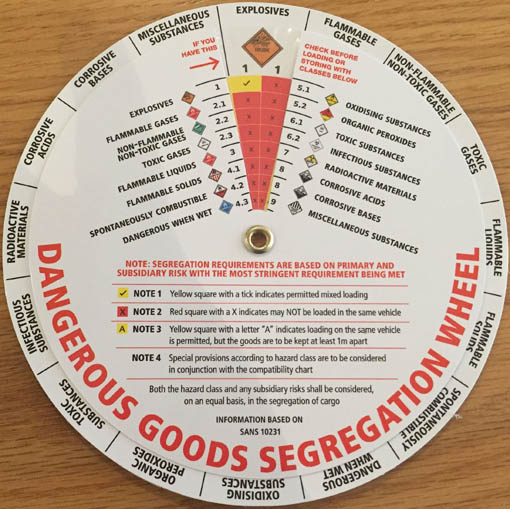

"CAIA has produced a Dangerous Goods Segregation Wheel that indicates the load and/or storage compatibility of mixed cargoes at a glance, using the class warning diamonds in an easy to use wheel. It assists in the segregation and storage of chemicals according to their hazard class. This prevents an undesirable chemical reaction from occurring should two or more chemicals accidentally mix. It also includes useful footnotes."

Explosives, Class 1 dangerous goods, sodium cyanide Class 6.1, sodium nitrate and potassium nitrate both of Class 5.1 all have compatibility restrictions. Explosives cannot be stored or transported with any other chemicals and Class 5.1 and 6.1 chemicals should not be stored in close proximity to each other nor transported on the same vehicle.

When packages that contain dangerous goods are packed into a freight container, the consignor shall provide a container-packing certificate, specifying the container identifying number and that the packing has been carried out in accordance with certain conditions. Among these key requirements are that clean, dry and fit containers do not contain goods that are incompatible; that packages have been externally inspected for damage or leakage and that only sound packages have been loaded; and that the freight container and all the packages have the correct labels and placards.

"This unfortunate incident demonstrates that the management, storage and transport of hazardous chemicals, without considering their compatibility, could have disastrous consequences," concludes Penfold.

CAIA launched the Responsible Care programme in South Africa in 1994. This is the global chemical industry's unique initiative to improve health, safety and environmental performance and to communicate with stakeholders about products and processes.

In addition to this programme, CAIA provides linkages to sustainability in the chemical industries' value chain through advocacy, training, support of educational drives in maths and science and the advancement of these concepts into sub-Saharan Africa.

CAIA is a member of the International Council of Chemical Associations (ICCA), the worldwide voice of the chemical industry, representing chemical manufacturers and producers all over the world and is recognised by the United Nations Environment Programme (UNEP). These international alliances allow the Association to source best practice in training, information, advocacy and legislative compliance. For more information, go to www.caia.co.za or call +27 11 482 1671.